To start airbrushing, you must first collect all the necessary airbrush equipment. This includes everything from the airbrush back to the air compressor, all air hose components, fittings and so forth…

Review this equipment list in depth and you will know exactly what airbrush equipment to buy in order to start off your airbrush journey right.

What do you need to airbrush?

For better understanding, follow along with me and I’ll paint a clear picture in your mind surrounding each one of these items.

You’ll learn,

What each item does, why it’s important, and which to choose based on the options associated with each.

From here on, consider me your personal airbrush gear guide!

Airbrush

The airbrush is essentially the brains of the operation. Its job is to atomize the paint using compressed air provided by the compressed air supply (Air compressor).

First thing, you will need an airbrush that is spec’d for the application you intend to use it for.

This means choosing an airbrush that is equipped with the functions and features that will provide you the most benefit on the project types you’ll be working on…

That being said,

There are a multitude of different airbrush types and styles to pick from. Most users opt for a double action, gravity feed airbrush. But depending on the application you have in mind; another style may suit your needs better.

Truth be told, you have on average, 3 different features to consider when selecting your airbrush

- The Flow Control Style

- The Paint Feed Type

- The Needle Size

From there, each has its own subset of options to choose from.

Learn more about the airbrush! From how it works, to the select options available to choose from. Get Answers to frequently asked questions and more!

Discover the traits of your next airbrush! Get the one spec’d precisely for your needs. I’ve got a couple of recommendations for you!

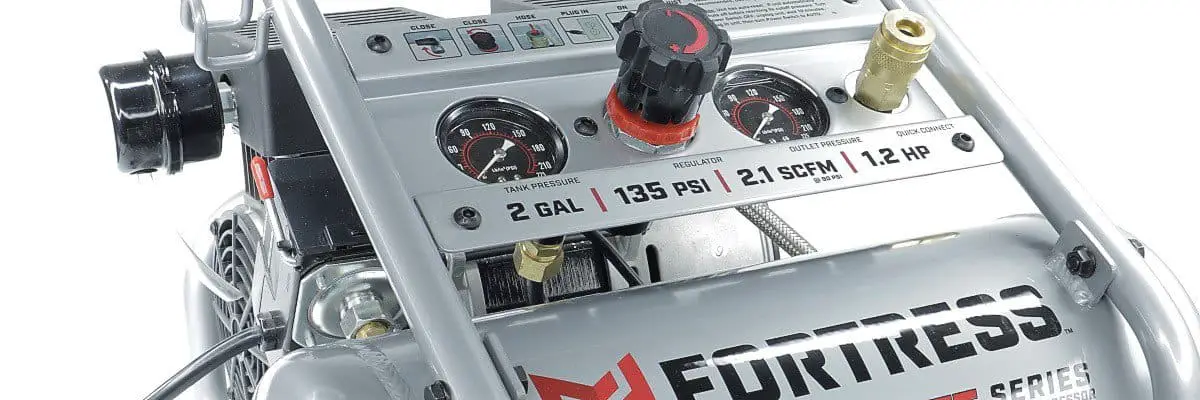

Air Compressor

A supply of compressed air is essential for an airbrush to function properly and efficient. The pressurized air flow is what atomizes the paint into microscopic particles that are then sprayed onto your artwork in a controlled mist like manner.

You will need a source of compressed air to which your airbrush can draw from.

Though most utilize an air compressor, you do have a couple of options to choose from when selecting a compressed air source:

Air Compressor

The air compressor is the most common method for generating compressed air for an airbrush. As it is the lowest cost (Long term), it is a self-rejuvenating air supply, and it is the most economical option out of those on this list. That being said, Most opt for a quiet, portable compressor, as they are far more airbrush friendly then the large stationary air compressors commonly found in auto shops and so forth. But truth be told, any compressor can be used for airbrush work, not just the small ones.

Pressurized Tank

Large, compressed air tanks commonly found at welding supply shops have been used by a select few airbrush artists across the industry. Though less common, compressed air tanks are virtually silent aside from the subtle hiss of air flow when in use. The pit fall thereof, is the fact it is not a self-rejuvenating air supply. This means, eventually you’ll have to make a run down to your local welding supply store and have it recharged every now and then.

Airbrush Propellant

Airbrush propellant is essentially a small (6-12oz) can of pressurized air. Usually only used for quick one-off jobs as these cans of airbrush propellant only provide, at most, about 10 minutes of usable air and can be expensive if used in bulk. The cans are not rechargeable to my knowledge, so each can is used on a one and done basis.

For the majority of airbrush users, I recommend using an air compressor. For most, the pro’s will simply far outweigh the con’s when compared against the alternatives. I personally use an air compressor and have for years, and the maintenance has been virtually nonexistent.

Learn the requirements an air compressor must meet to be viable for airbrush use. Get answers to frequently asked questions and more!

Discover what to look for when selecting an airbrush compressor, as well, what to avoid. Get recommendations based on what’s available on the market today.

Air Line

In order to get the compressed air from your air supply to your airbrush, you are going to need an air line. An air line is essentially a sequence of components that allows the air from your air supply to be cleansed and transferred from your air supply to your airbrush.

Simply speaking, this is how you connect your airbrush to your air supply, via an air line.

Simply speaking, and airbrush air line consists of the following components:

- Air Hoses

- Air Filters

- Fittings

- Adaptors

- Air Sealants

An air line can be very complex including multiple T-adaptors and intersections that allow for multiply airbrushes to be used from a single air source.

To very simple utilizing simply an airbrush air hose, and a couple fittings and adaptors to connect everything properly.

Its all up to you.

Learn the components that make up an airbrush air line. As well as, how to integrate each part into your air line for consistently clean air flow to your airbrush, no matter where you workstation is located.

Airbrush Tools & Accessories

Once you have everything you need to start airbrushing. I greatly urge you to then consider some of the tools and accessories available to you that will enhance your airbrush experience and the appearance of your finished projects.

For improved usability of your airbrush, see my complete list of recommended airbrush tools and accessories.

Conclusion

Now, you should have a good understanding as to what airbrush equipment you need for airbrushing, the options you have, and how to start piecing each part together.

For most basic setups, their airbrush equipment list consists of:

- Airbrush

- Air Compressor

- Pressure Regulator

- Airbrush Air Line

More advanced setups will include T-fittings with multiple air line hookups that allow multiple airbrushes to be used off the same air supply, larger air compressors, and significantly longer air hoses to keep the noise of the air compressor some distance away from the user’s workspace.

Once you’ve reviewed this airbrush equipment list, you’ve got your equipment setup, and everything connected properly. Now, let’s get some color in your airbrush and learn about the relationship between paint viscosity and air pressure!

Before you spray, Learn about color selection, paint reduction, and later, air pressure.